Therefore, a square tolerance zone defined at +.005 and -.005 is actually +.007 and -.007 worst case.

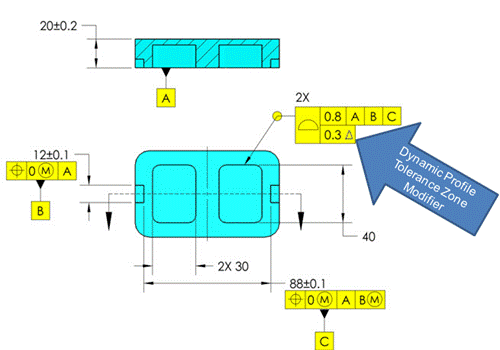

This is the actual worst scenario for which the hole features may be manufactured (.014 or +. In figure 2, there is a dimension attached to the top left and bottom right corners. 010 at some location, which as illustrated in figure 2. This means the derived center of each of the holes must fall within a square tolerance zone. In the mechanical drawing given in figure 1, there are four holes drilled thru the block, and each hole's location relative to each other and the edges are specified using a limit tolerance of a distance and +.005 and -.005. GD&T allows the use of round tolerance zones as opposed to square or rectangular tolerance zones as given by limit tolerancing methods for cylindrical (holes, shafts) features.

#Asme y14.5 – 2009 verification#

Additionally, the use of datums dramatically simplifies the design and specification of fixtures for use in manufacturing and quality verification steps.

Without the use of a datum system (zero reference) on a part, it is not clear to manufacturing or quality where to manufacture or measure from. A datum is just a fancy word for saying which specific feature on a part will be used as a reference (zero) for tolerance calculations, dimensional measurement, and most importantly, from where the feature(s) manufacturing should build from to ensure a consistent part. GD&T facilitates an efficient means to communicate specific datums on a part. Some distinct advantages of GD&T are as follows: Success oriented organizations, which require accurate and common lines of communications between engineering, design, manufacturing, and quality should consider (GD& T) as their mechanical drawing standard. In today's modern and technically advanced design, engineering and manufacturing world, effective communication is required to ensure the design and manufacture of successful products.

#Asme y14.5 – 2009 iso#

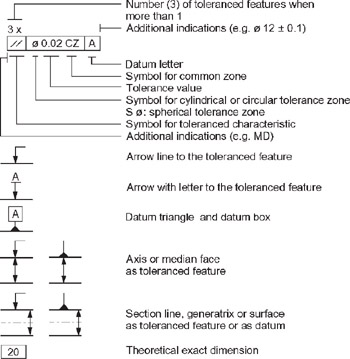

The ASME Y14.5-2009 and Geometrical Product Specifications ISO 1101(e)-2004 series are very similar and provide identical means to specifiy dimensional requirements. GD&T, both ASME Y14.5-2009 and Geometrical Product Specifications ISO series are the only recognized international drawing standards in use throughout the world. GD&T is, and has been, successfully used for many years in the automotive, aerospace, electronic and the commercial design and manufacturing industries. GD&T ) is a language of symbols used on mechanical drawings to efficiently, and accurately communicate geometry requirements for features on parts and assemblies. ASME Y14.5-2009 geometric dimensioning and tolerancing (

0 kommentar(er)

0 kommentar(er)